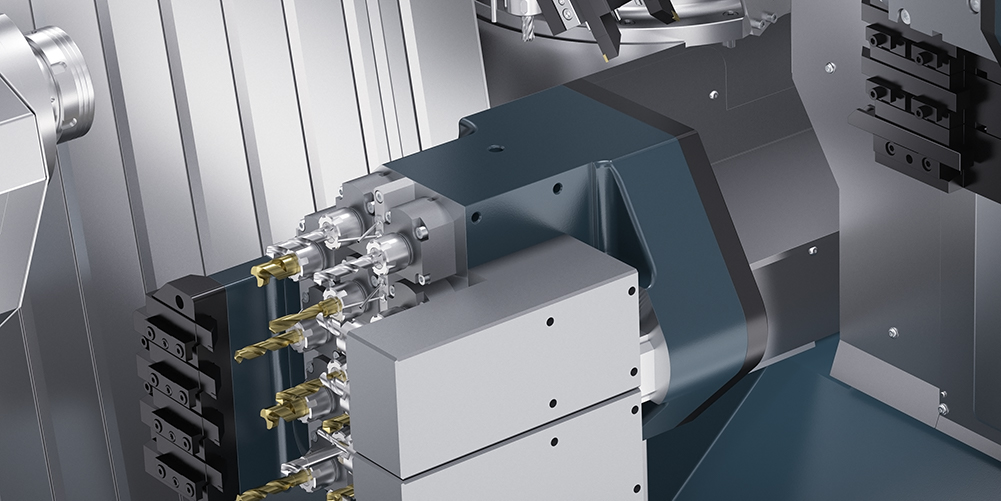

Secondary operations

All the configurations have three completely independent tool systems, the same secondary operation block, and a platen to the right of the guide bush. The SwissDECO features an extremely rich secondary operation block: indeed, it is quite simply the richest one currently on the market. The machine can be equipped with up to 16 tools, 12 of which are rotating. In order to form a coherent assembly, the secondary operation block has a very high drive power. The tools drive alone features an 8.2 Nm torque, providing a maximum rotation speed of 10,000 rpm. The machine's left-hand platen is fully modular, and adaptable to the requirements of the workpiece. It is possible to install chisel holder plates, radial drills/milling tools, a horn or even special devices. The platen features completely autonomous X and Y movement capability. It rests on high-precision solid guides, giving the assembly excellent rigidity, and the platen enables very fast chip-to-chip times. The difference between the SwissDeco versions lies in the latest tool system, taking the form of either a turret or a platen. These two devices feature X and Y movement capability, and are also equipped with a Z axis enabling them to work in differential mode and, for example, perform stroke progression for operations.